Automatic CNC Pipe and Tube Bending Machine Stainless Steel Carbon Steel Metal Pipe Bending Machine

£9.200,00£18.400,00 (-50%)

- Is Smart Device: YES

- Model Number: WE67K

- Condition: New

- CNC or Not: CNC

- Brand Name: UNICHCNC

- Origin: Mainland China

- Certification: CE

- Place of Origin:: Shandong, China

- Machine Type:: Press Brake

- Machinery Test Report:: Provided

- Core Components:: servo motor

- Raw Material:: Sheet / Plate Rolling

- Power:: Hydraulic

- Key Selling Points:: High-accuracy

- Shearing Angle:: 0.5°-2.5

- Motor Power:: Siemens

- Processing material: Metal Stainless Steel Carbon Steel

- Weight (KG):: 1600

- Warranty:: 3 years

- Backgauge Travel:: 20 – 1000 mm

- Cooling method:: Water cooling

Automatic CNC Pipe and Tube Bending Machine Stainless Steel Carbon Steel Metal Pipe Bending Machine

Machine discription:

Cnc Metal Bending Machine (Optional)

CNC bending machines can be used to shape metal sheets into different shapes in various sizes.

It can bend non-ferrous metal,ferrous metal sheet, suitable for various industries requiring metal processing, such as decoration manufacturing, automobile and ship manufacturing, aerospace manufacturing, etc.

Machine Features

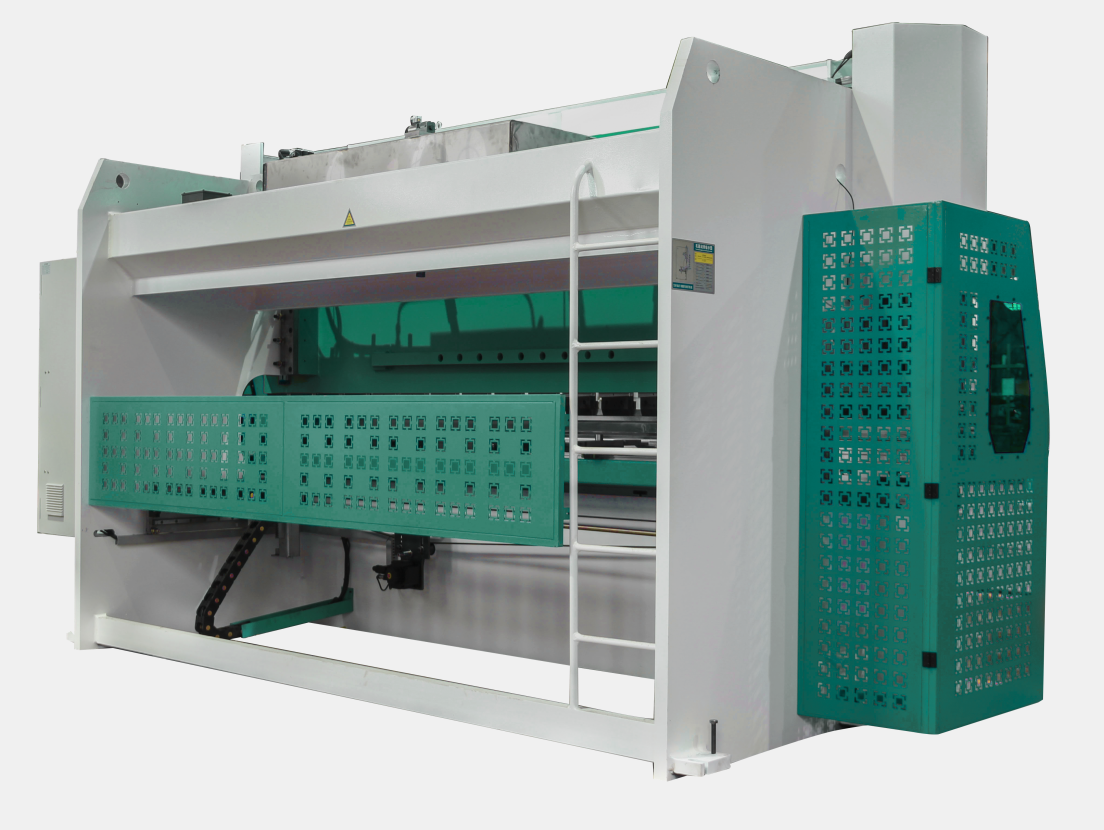

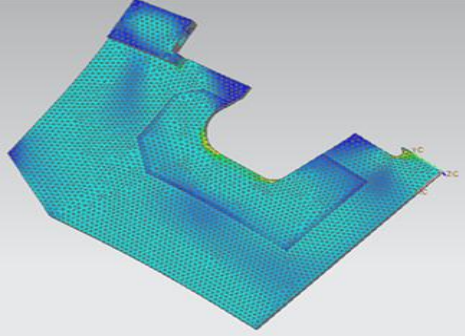

1. The machine body adopts the structure of integrally weld and integrated machining, and the main parts of the machine use ANSYS finite element analysis software to analyze, which ensures the reliability of the machine and the precision of the entire machine.

2. The main oil cylinders fitted on both sides adopt closed loop control mode which iscomposed of Germany electro-hydraulic servo valve and imported grating ruler, breaking through the stroke control mode of traditional mechanical stop bending machines, ensuring the high precision of the glide position, the accurate and stable operation, the high precision of bending, and high precision of the repeated positioning of slider.

3. The functional components of the back gauge are all imported, ensuring the stopping precision. The machine also can adopt more functional multi axis blocking according to the customers’ requirements.

4. The hydraulic system adopts integrated control system imported from Germany, which decreases the installation of pipelines and ensures working stability of the machine tool and conciseness and beauty in appearance.

5.C-shaped plates are fitted on both sides of the machine body, and the high precisiongrating ruler is fitted on the C-shaped plate. Thus to avoid the influences on bending precision arising from distortion of machine body during bending process.

6. The lower workbench is fitted with hydraulic automatic deflection compensation mechanism, ensuring effective compensation without blind area and high precision of bending so that long stability is guaranteed.

The consumer can choose the machine according to the material thickness and processing width of the sheet metal. Here is 3 types,simple, efficient, electro-hydraulic, each type can provide a different width for selection. We can manufacture any type of

non-standard product according to the special requirements of our customers.

Machine parameters:

|

1

|

Machine Name

|

Hydraulic CNC bending machine

|

|

2

|

Model

|

WE67K 70T 1600(Multiple models available)

|

|

3

|

Controller

|

Netherlands Delem DA53T

|

|

4

|

Main motor

|

Siemens motor

|

|

5

|

hydraulic valve

|

Rexroth proportional value

|

|

6

|

Ball screw transmission

|

Taiwan Hiwin

|

|

7

|

Cylinder seal

|

Japan NOK

|

|

8

|

Hydraulic oil pump

|

China high quality

|

|

10

|

Back barrier Double linear guide

|

Taiwan Hiwin

|

|

11

|

Grating Protection

|

Italy Givi company

|

|

12

|

Electrical device

|

French Schneider

|

Machine main parts:

Product structure

1. Utilize UG analysis method to optimize the design and achieve an attractive appearance.

2. The machine is welded with steel plate and has sufficient strength and rigidity so as not to cause serious overload accidents due to improper operation.

3.Cylinders are equipped with mechanical stops to ensure repeat positioning accuracy and uniform bending angle.

Hydraulic system

1. The most advanced fully closed loop electro-hydraulic servo synchronization control system;

2. High precision guide system, position measuring system and hydraulic equalization function can satisfy the processing requirements of full length or eccentricity.

3. It can work continuously under rated load. The hydraulic system guarantees no leakage and stable processing with high precision.

Bench deflection compensation system

1. Compensation system is the CNC axis of the convexity of the control table, which can obtain the accuracy on the whole length of the table.

2. It automatically calculates the required compensation and controls the relative movement of the convex wedge, thus effectively compensating the deflection deformation caused by the slider and the workbench.

3. The deflection compensation workbench is maintenance-free during the life of the machine tool.

Numerical control system

_2D Touch Graphics Programming

_3d Product Graphic Simulation Display

_High resolution TFT true color display

_Complete Windows Application Package

_Compatible with Delem modular structure system

_User program application in multi-task environment

_Angle detection sensor interface

_Profile-L Offline Programming Software

Machine Application:

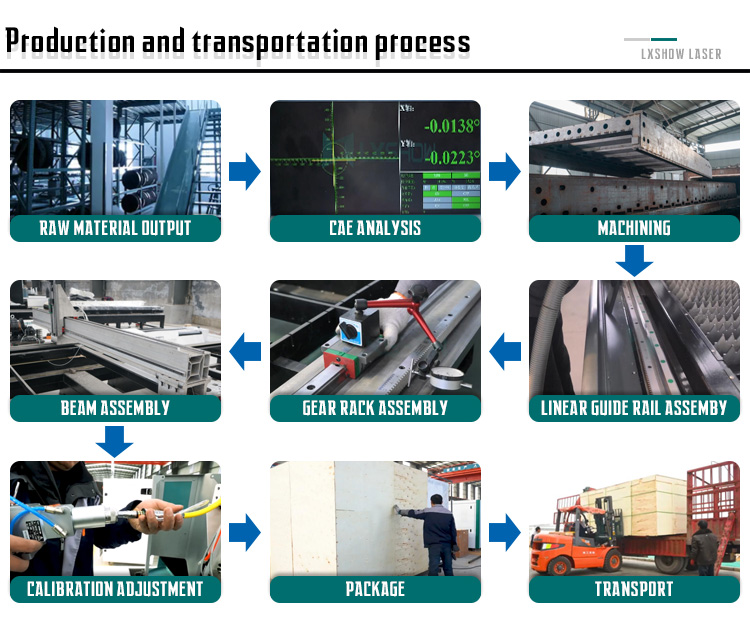

Company profile

* 17 years factory production experience

* 3 years machine warranty

* 156 exported country experience

* 32000 square meters fiber laser cutting machine factory

Jinan Lxshow Manufacture & Trading Co., Ltd.,

is established in July 2004 ,owns more than 500 square meters of researching and office space,

more than 32000 square meters factory.All machines , passed the European Union CE authent-

ication. Products are sold to USA,Canada, Australia, Europe, South east Asia,Africa etc,more than 150 countries and areas,and supply OEM service for more than 30 manufactures.

Now, we have owned four International brand, JNLINK, LXSHOW,UNICHCNC,MYST.

Our Products includes All kind of

1. Fiber laser welding / cleaning machine.

2.Fiber laser cutting machine.

3.Laser marking machine(Fiber/CO2/UV/Green light)

4.CNC bending machine

We can also customized non-standard assist equipment as your detailed work requirements.

Why choose us?

1). 2 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

2). Lifetime maintenance free of charge.

3). Free training course at our plant.

4). 24 hours on line service and email each day, free technical support.We will reply you in 24 hours after receive your problem of the machine.

5). Machine has been tested and adjusted before delivery.We will take machine photos and make machine working image for you ,after getting your agreement ,then we will book a ship.

6). Provide technical services to the door(We have professional engineers to offer machine installation commissioning and maintenance) if customers pay the charges of ticket.

7). If you have any problem during your use.you need our technician to judge

Where the problem is and help you to solve it. We can provide team viewer and skype with cam till all of your problems solved.

Welcome to our factory

Customer feedback

FAQ:

Q: What accessories will be included with the purchase of the machine?

A: bending mold,front bracket,foot switch,Laser protection,floor screw and so on

Q: If we are interested in your machine, how do we choose?

1. What main job you do with the machine? We can make different molds according to your different needs

2. What is your request max working area? __mm* __mm?

3. What’s your material thickness & length?

4. What material you want to bending?

Please tell us, then we can recommend the suitable machine to you.

Q: What are the differences between the three types of machines? Which one should I choose?

We have 3 models bending machine for your choice.

1 Electro Hydraulic bending machines

2 efficient bending machines

3 simplebending machine.

The work efficiency is 1>2 >3. also the price is a 1>2>3.

if you can’t confirm, We will quote 3 kinds, then you can choose according to your budget.

Q: How about warranty?

A: 3 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the

world, We need your machines running in order to keep your business running.

Please contact

Sales manager: Renee Hou

Email: export46@lxshow.net

Tel/WhatsApp/WeChat:+86 180 6348 1132

Website: https://www.lxslaser.com/

https://www.lxshowlaser.com/

https://www.laserlx.com/